Product Video

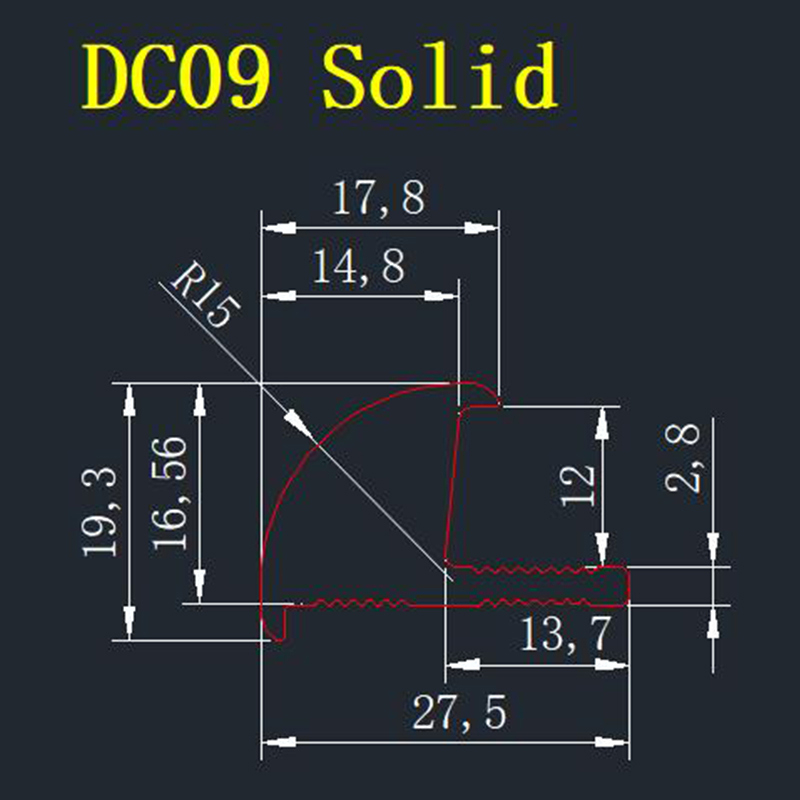

PVC tile trim, Model No.: DC09, Solid, Width: 27.5mm, Height: 16.56mm+2.74mm.

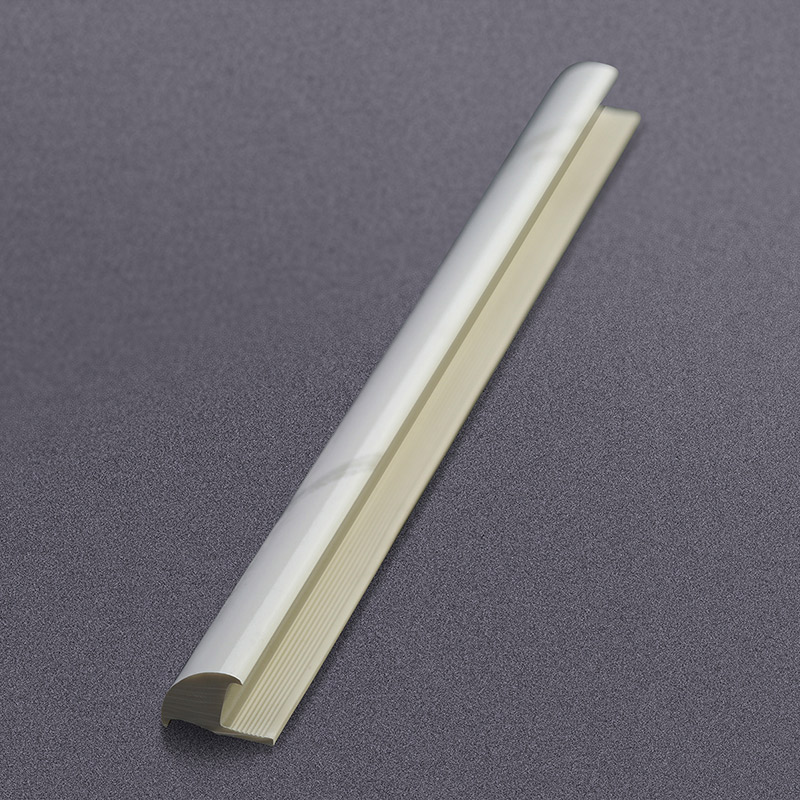

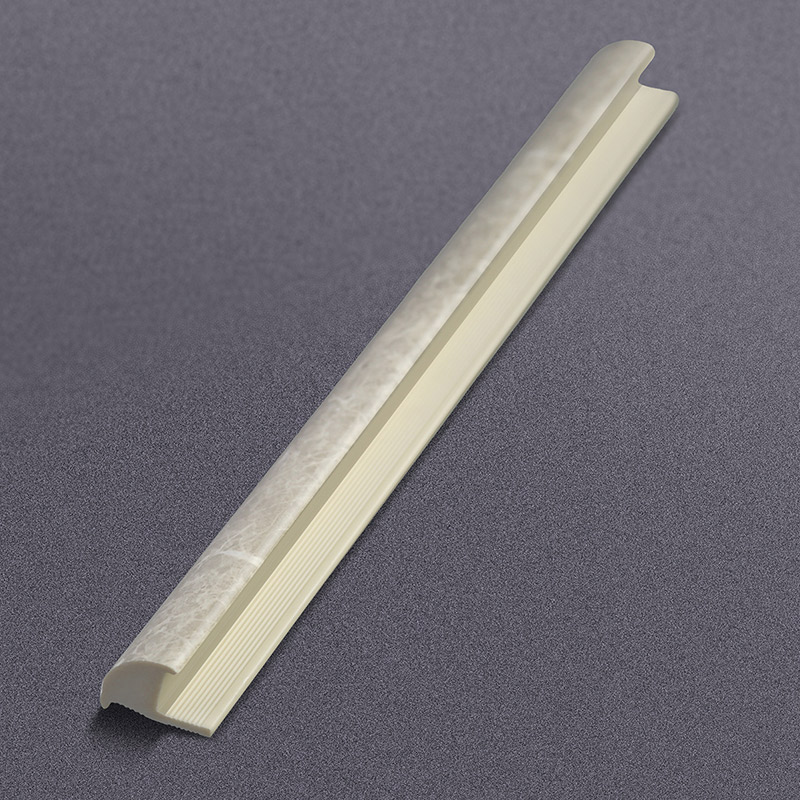

Adopt international advanced thermal transfer technology, clear and realistic stone texture, rich layers, strong three-dimensional sense.

The products are made of excellent materials, advanced technology, compression resistance, folding resistance, freezing resistance, impact resistance, wear resistance and waterproofing.

Tile trim can be used to decorate corners as well as edges, such as the edge of the skirting top line, the base line, etc.

It is used to decorate the corners of the tile paving in the decoration project. The tiles are pasted on the wall through the special sticking holes for the tile trim, so that a beautiful arc surface is formed at the corner. It is suitable for the connection of tiles laid at the corners of the wall, making the overall paving effect more neat and elegant.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About PVC Tile Trims

| Material | PVC |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

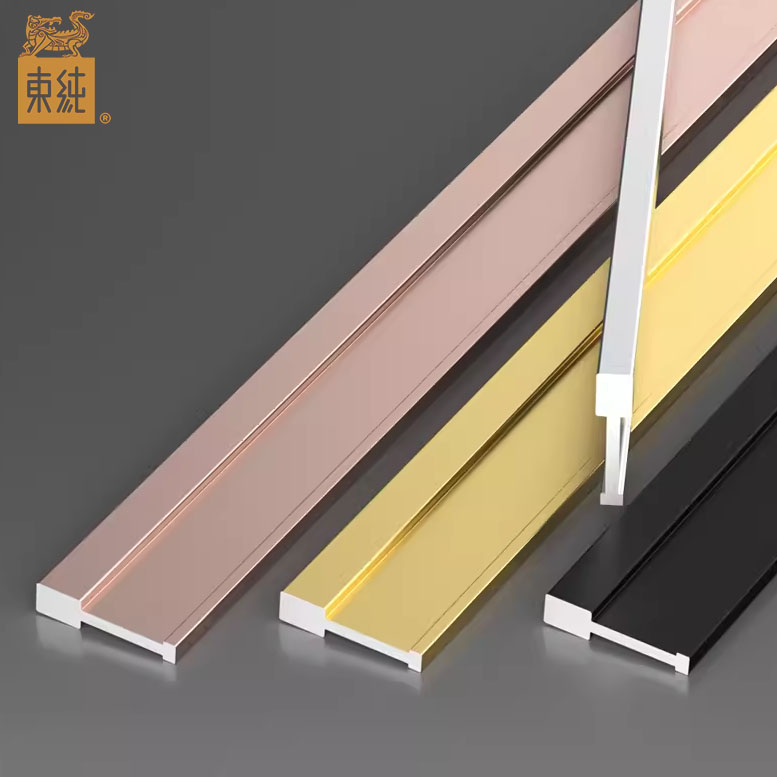

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Open/Solid/Edgeless/Triangel hole/Two edges/Semicircle/Large semicircle/Right angle/F buckle/Airplane shape | |

| Surface Treatment | Thermal transfer printing |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners