Product Video

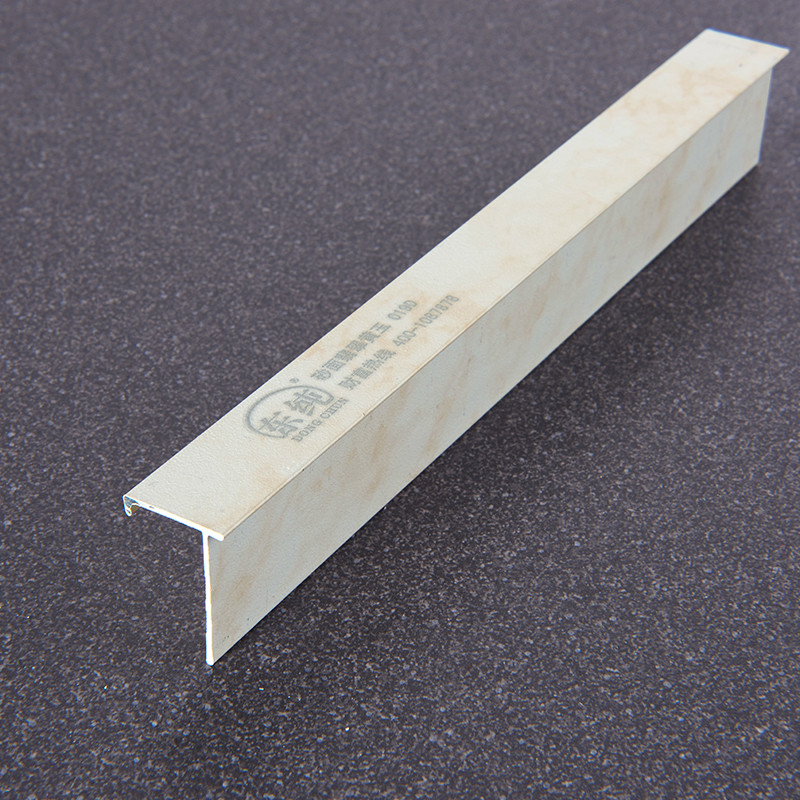

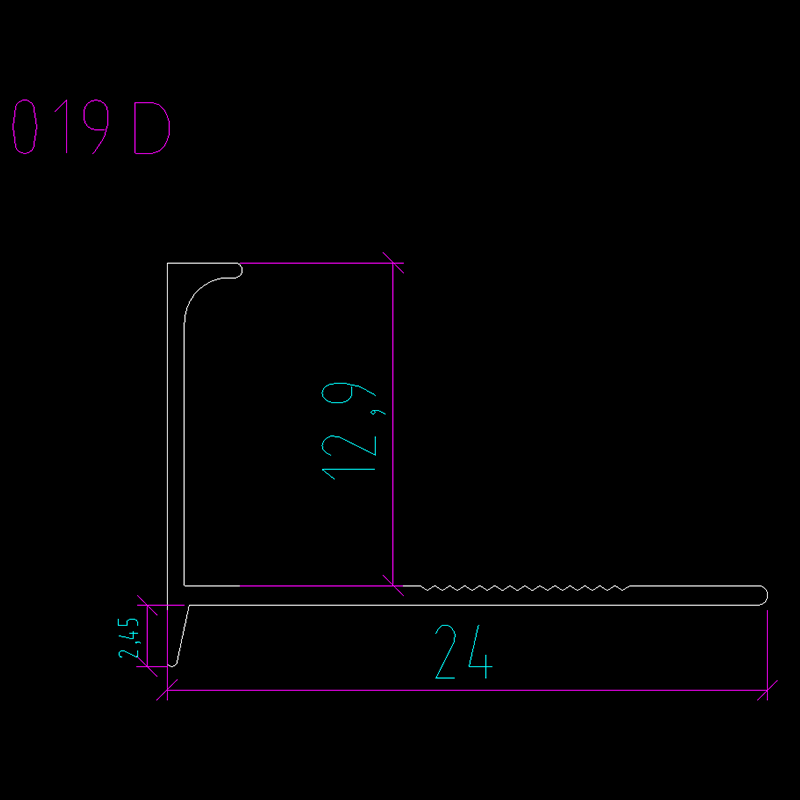

019D, Aluminum tile trim, L shape.

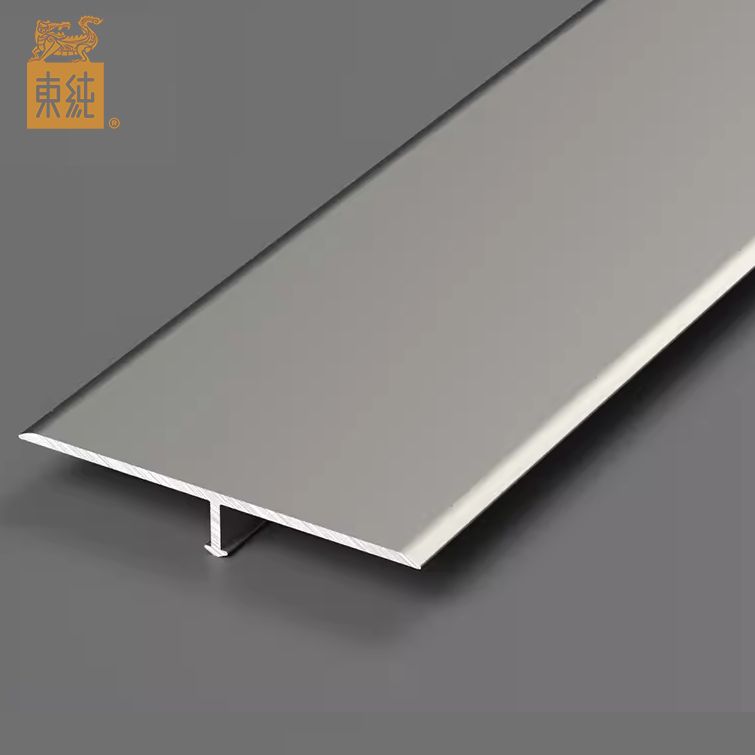

There are anti-skid teeth or perforated patterns on the bottom plate, which are easy to be fully combined with the wall and tiles.

The edge has a limit edge, which is used to constrain the installation position of the tile or stone.

Existing mold, color and length can be customized according to your market demand.

Product production adopts hot extrusion molding, aging treatment, spraying process and thermal transfer printing process.

Free samples are available.

OEM/ODM are available.

The damage to the decoration without the use of tile trims.

1. The tile grinding operation requires a large amount of work and requires high grinding skills for workers.

2. When the tiles of poor quality are edging, the edges will not be straight, and the edges will be easy to burst.

3. After the tiles are edged, the edges of the tiles become thin, fragile and easy to break.

4. The noise and dust pollution caused by edging do not meet the trend of environmental protection.

5. After a long time, there will be gaps in the joints of the tiles, and the entry of dust will cause them to become dirty and unsanitary.

View more shapes from CAD DRAWING

265+ tile trim shapes for your choice, or send us your CAD file for quotation.

More About Aluminum Tile Trims

| Material | Aluminum alloy |

| Specification | 1.Length: 2.5m/2.7m/3m |

| 2.Thickness: 0.4mm-2mm | |

| 3.Height: 8mm-25mm | |

| 4.Color: White/Black/Gold/Champagne, etc. | |

| 5.Type: Closed/Open/L shape/F shape/T shape/Other | |

| Surface Treatment | Spray coating/Electroplating/Anodizing/Polishing, etc. |

| Punching Hole Shape | Round/Square/Triangle/Rhombus/Logo letters |

| Application | Protecting & Decorating the edge of tile, marble, UV board, glass, etc. |

| OEM/ODM | Available. All of above can be customized. |

Our company has 16 years experience in production, professional technicians and one-stop production lines, including mold design, aluminum profile manufacturing, machining (heat treatment, profile cutting, stamping, etc.), finishing (anodizing, painting, etc.) and packaging. Efficient and convenient production, ensure product quality standards, and ensure on-time production delivery.

Tile Trims Series

Color Chart

Tile Trims Style

Cooperation Partners